Ever wondered how ice cream travels miles from a factory to your freezer, perfectly preserved? Or how fresh bread reliably appears on supermarket shelves every morning? The answer lies in the precise and intelligent management of production and the supply chain within the food industry. In today’s competitive landscape, this management goes far beyond mere manufacturing; it’s a complex orchestration of resource allocation, stringent quality control, seamless supplier collaboration, and efficient distribution. Companies that masterfully conduct this orchestra not only optimize costs and boost profitability but also deliver superior quality, earning vital consumer trust and satisfaction.

Of course, this path is paved with challenges. Fluctuating demand, cost pressures, distribution complexities, and the constant need for innovation are ever-present hurdles. These challenges are amplified in the food industry, where product perishability and consumer sensitivity to quality and safety are paramount. Effectively integrating the entire chain – from farm or supplier through processing, distribution, and retail – often marks the difference between a thriving food business and one that fails.

In this comprehensive guide from Foodex Magazine, we journey into the heart of this critical industry function. We’ll explore the key stages of production, core objectives, common challenges, effective strategies like Lean and Agile manufacturing, essential quality management techniques, and exciting future trends such as IoT and AI. Our goal is to provide deep, practical insights to help you master the best practices in production and supply chain management, setting your business on a path of sustainable growth. At Foodex, we believe that by sharing knowledge and facilitating the right connections and tools, we can help smooth this path for you.

Join us as we first clarify the concept of production within the supply chain, then delve into the main stages, challenges, solutions, and future outlook.

What is Production within the Food Supply Chain?

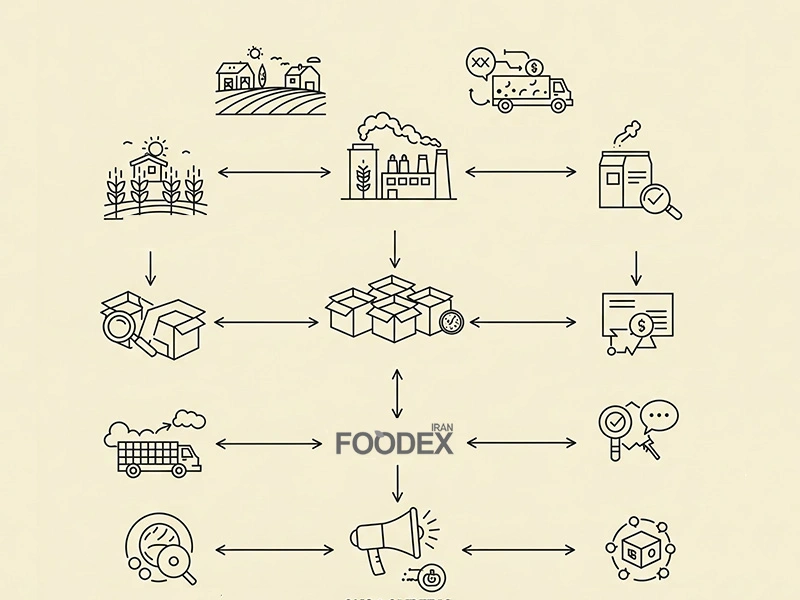

Production is the beating heart of the food supply chain. It’s the critical process where raw agricultural materials (like grains, milk, or fruit) and ingredients are transformed into the safe, high-quality, value-added food products that consumers demand (such as bread, cheese, or juice). This concept extends far beyond the factory floor; it encompasses the management, support, and precise coordination of the entire journey – from sourcing raw materials, through manufacturing and packaging, to storage and final distribution to the end consumer.

Essentially, it maps the flow: raw materials move from farms or suppliers to processing plants; they are converted into finished goods; and then they travel via logistics networks, often involving temperature-controlled storage and transportation, to distributors, retailers, and ultimately, to the consumer’s table.

While specific segments of the food industry (dairy, meat, bakery, beverages, etc.) have their unique operational nuances, the fundamental stages involved in this production process follow a common framework, which we will explore next.

Key Stages in the Food Production & Supply Chain Process

While specifics can vary across food sectors, the journey from concept to consumer generally follows these key stages:

1- Product Design & Development

This initial stage is where innovation takes shape. Food scientists, R&D specialists, and marketing teams collaborate to define the specifications for a new or improved product. Key considerations include taste profile, texture, nutritional value, available raw materials, target shelf life, packaging requirements (for preservation, safety, and consumer appeal), adherence to food regulations, and, crucially, the feasibility of consistent, large-scale production.

Example: A snack company decides to launch a new line of baked vegetable crisps. The R&D team develops the recipe, determines the optimal baking time and temperature, selects appropriate (perhaps recyclable) packaging film to maintain crispness, and finalizes nutritional information and ingredient declarations for the label.

2- Procurement & Sourcing

Once the design is finalized, the focus shifts to sourcing the necessary inputs: raw agricultural materials (like grains, fruits, vegetables, meat, milk), other ingredients (oils, spices, additives), and packaging materials (films, cartons, jars, labels). This involves identifying reliable suppliers (farmers, growers, ingredient manufacturers), negotiating contracts based on quality specifications and price, managing supplier relationships, and often dealing with the seasonality and inherent variability of agricultural supplies.

Example: A tomato processing plant needs to secure contracts with tomato growers months in advance to ensure a sufficient supply of tomatoes meeting specific quality criteria (e.g., color, acidity, Brix level) during the short harvest season.

3- Quality Control of Incoming Materials

This step is critical for ensuring the safety and quality of the final product. Before raw materials enter the production line, they undergo rigorous checks against predefined standards. This typically includes visual inspection (for freshness, damage, foreign matter), physical tests (e.g., size, moisture content), chemical analysis (e.g., pH, fat content, potential contaminants like pesticides), and microbiological testing (for harmful bacteria).

Example: A dairy processing facility tests incoming raw milk for temperature, antibiotic residues, bacterial counts, and composition (fat, protein) before accepting it for pasteurization and further processing into products like yogurt or cheese.

4- Production Planning & Scheduling

This stage determines what products to make, in what quantities, when, and using which resources. Planning relies heavily on demand forecasts (considering seasonality, promotions, market trends), current inventory levels (especially for short-shelf-life products), production line capacity, and the availability of raw materials. The goal is efficient production that minimizes stockouts while avoiding overproduction and potential waste.

Example: A large bakery plans its daily production of different bread types based on historical sales data per weekday, anticipated weather impacts (which can affect demand), and confirmed orders from supermarkets, ensuring fresh bread is available while minimizing unsold loaves.

The History of Supply Chains

From Ancient Times to the Modern Era5- Manufacturing & Processing

Here, the sourced raw materials are transformed into the finished food product according to specific formulations and processing instructions. Food manufacturing involves diverse operations like cleaning, cutting, mixing, cooking, baking, pasteurizing, sterilizing, drying, fermenting, freezing, filling, etc., using specialized equipment. Strict adherence to process parameters (time, temperature, pressure) and hygiene protocols (GMP) is essential for product quality and safety.

Example: In a beverage plant, fruit concentrate, water, and other ingredients are precisely mixed, pasteurized at a specific temperature for a set duration to ensure safety, cooled rapidly, and then filled into sterilized bottles or cartons under aseptic conditions.

6- Quality Assurance (QA)

QA is a process-oriented approach focused on preventing problems before they occur. It involves establishing and maintaining systems, standards, and procedures (like HACCP, ISO 22000, GMP) to ensure the entire production process is capable of consistently producing safe, high-quality products that meet all specifications. It’s about building quality into the system through controlled processes, documented procedures, training, and audits, rather than just inspecting the final product.

Example: A ready-meal manufacturer implements a HACCP plan identifying critical control points (CCPs) like cooking temperatures and metal detection. They establish monitoring procedures for these CCPs, define corrective actions if deviations occur, and keep meticulous records, ensuring the entire process is managed to prevent food safety hazards.

7- Packaging & Labeling

After production and quality verification, products are packaged. Food packaging serves multiple crucial roles: protecting the product from physical damage, contamination, and quality deterioration (e.g., light, oxygen, moisture); extending shelf life; providing convenience to the consumer; carrying branding and marketing messages; and conveying essential information via the label. Labeling must comply with strict regulatory requirements regarding ingredient lists, nutritional information, allergen warnings, date marking (use-by or best-before dates), net weight, origin, and storage instructions.

Example: A coffee company packages its roasted beans in foil-lined bags with a one-way valve (to let CO2 escape without letting oxygen in) to preserve freshness. The label clearly indicates the bean origin, roast level, net weight, best-before date, and brewing recommendations.

8- Inventory Management

Finished goods are stored (in ambient, chilled, or frozen warehouses depending on the product) before shipment. Managing food inventory is particularly challenging due to perishability. The goal is to optimize stock levels to ensure product availability while minimizing holding costs and, critically, reducing the risk of spoilage or expiration. This often involves strict adherence to stock rotation principles like FIFO (First-In, First-Out) or, more appropriately for food, FEFO (First-Expired, First-Out).

Example: A producer of fresh bagged salads uses the FEFO system rigorously in its cold storage warehouse. Pallets of salad bags are marked with expiration dates, and the system ensures that bags with the nearest expiration dates are always shipped out first to retail customers.

9- Distribution & Logistics

This involves moving the final product from the factory or warehouse to the customer (wholesalers, retailers, food service outlets, end consumers) through various channels. Key activities include transportation planning (routing, scheduling), selecting appropriate transport modes (standard trucks, refrigerated or frozen vehicles for the cold chain), warehouse management at distribution centers, and coordinating timely delivery while maintaining product integrity and temperature control throughout transit.

Example: A frozen pizza manufacturer uses a network of third-party logistics (3PL) providers specializing in frozen transport to deliver its products from its production facility to regional distribution centers and then to supermarket chains across the country, ensuring the pizzas remain frozen solid throughout the journey.

10- Customer Delivery & After-Sale Support

The final step involves ensuring the product reaches the customer in good condition and handling any subsequent interactions. For food products, this primarily involves managing customer feedback and complaints regarding quality, packaging, or labeling issues. In rare but critical instances, it also includes managing product recalls efficiently and effectively if a safety issue is identified. Handling these interactions professionally directly impacts customer satisfaction and brand reputation.

Example: A breakfast cereal company provides a customer hotline and online portal for consumers to ask questions about ingredients or report any quality issues (e.g., finding a clumped portion in the box). They have a system to track complaints and, if necessary, trigger investigations or recalls.

Key Objectives for Production in the Food Supply Chain

To achieve sustainable success, production and supply chain operations in the food industry must pursue a set of crucial objectives. These go beyond general manufacturing principles and incorporate the unique considerations of this sector:

1- Ensuring Food Safety & Compliance

This is arguably the most critical objective. It involves guaranteeing that all food products are safe for consumption and free from physical, chemical, or biological hazards. This requires strict adherence to national and international food safety regulations and standards (like HACCP, GMP, and those set by bodies such as the FDA or EFSA) at every single stage, from farm to fork.

2- Maintaining Product Quality & Consistency

Beyond safety, products must consistently meet consumer expectations regarding taste, texture, appearance, aroma, and nutritional value. Maintaining uniform quality across different production batches and throughout the product’s shelf life is vital for building and retaining customer loyalty.

3- Reducing Costs & Increasing Efficiency

Optimizing processes to lower the costs of production (raw materials, energy, labor) and distribution (transport, warehousing). In the food industry, this objective is tightly linked to minimizing food waste and spoilage throughout the chain, which is a major source of financial loss.

4- Ensuring On-Time Delivery & Freshness

Making sure products reach the market and the customer as scheduled is crucial, especially for perishable items with short shelf lives. Any delay in the cold chain or distribution can lead to quality degradation or render the product unsellable, directly impacting revenue and potentially damaging brand reputation.

5- Optimizing Inventory Management

Striking the right balance between having enough stock to meet demand and avoiding excessive inventory buildup is essential. Excess inventory increases the risk of spoilage and expiration, ties up capital, and incurs high holding costs (especially for refrigerated or frozen goods). Implementing FEFO (First-Expired, First-Out) or FIFO stock rotation methods is critical here.

For a deeper dive into optimizing inventory, explore our comprehensive guide on Inventory Planning and Management in the Food Industry Supply Chain.

6- Achieving Flexibility & Market Responsiveness

The ability to quickly adapt production and sourcing plans to unexpected shifts in customer demand (driven by trends, seasons, promotions), fluctuations in agricultural raw material supply (due to weather, harvest yields), and changing market dynamics is key to staying competitive.

7- Integrating the Supply Chain & Ensuring Transparency

Fostering coordination, collaboration, and a smooth flow of information among all chain partners (suppliers, manufacturers, logistics providers, distributors, retailers) improves overall efficiency, enables rapid response to issues, and enhances traceability.

8- Enhancing Traceability

The ability to track and trace products and their ingredients through every stage of the supply chain, from origin to point of sale. This is vital for crisis management (e.g., product recalls), ensuring authenticity, meeting regulatory requirements, and building consumer trust.

9- Promoting Sustainability & Social Responsibility

Reducing the environmental footprint of production and distribution (managing water, energy, waste), sourcing raw materials responsibly, using eco-friendly packaging, and adhering to ethical labor practices are increasingly important objectives driven by consumers, regulators, and corporate values.

10- Ensuring Workplace Safety & Health

Creating and maintaining a safe working environment for all employees involved in food production and logistics. This includes identifying and controlling specific industry hazards (e.g., machinery operation, temperature extremes, cleaning chemicals, slippery surfaces).

Production and Supply Chain Challenges in the Food Industry

Achieving the ambitious objectives outlined previously is no simple task in the food supply chain. Industry players face a complex and unique set of challenges that require intelligence, flexibility, and innovative solutions to manage effectively. Some of the most significant hurdles include:

1- Managing Perishability and Short Shelf Life

Many raw materials and finished food products (like fresh dairy, meat, fruits, vegetables, and bread) have a limited shelf life. This puts immense pressure on production speed, demand forecasting accuracy, inventory management (requiring FEFO), and maintaining the cold chain, significantly increasing the risk of spoilage and waste.

2- Coping with High Demand and Supply Volatility

Food demand can fluctuate significantly due to seasonality, holidays, health trends, promotions, and even weather patterns. Simultaneously, the supply of agricultural raw materials is highly dependent on weather conditions, pests, diseases, and harvest cycles, making production planning and forecasting exceptionally difficult.

3- Ensuring Food Safety Throughout the Chain

Preventing microbial, chemical, and physical contamination at every stage – from the farm through processing, packaging, and transportation – is a constant and critical challenge. Any failure can lead to consumer illness, costly product recalls, severe brand damage, and serious legal consequences.

4- Navigating Complex and Evolving Regulations

The food industry operates under intense scrutiny from national and international regulatory bodies (e.g., FDA, EFSA). Constantly changing laws related to standards, labeling (ingredients, allergens, nutritional info), permitted additives, import/export requirements, and hygiene protocols demand constant vigilance and compliance efforts, which can be costly and complex.

5- Managing Complex Supplier Networks

Food supply chains often involve numerous suppliers, particularly small, geographically dispersed farms and growers. Ensuring consistent quality from diverse sources, establishing fair pricing, verifying compliance with safety and environmental standards, and managing long-term relationships present significant challenges.

Common Challenges in Demand Planning

Learn More6- Balancing Cost Pressures with Quality Maintenance

Fierce market competition creates intense pressure to reduce costs. However, cost-cutting cannot come at the expense of product quality or safety. Finding this balance is increasingly difficult with rising input costs for energy, raw materials, and transportation.

7- Meeting Demands for Transparency and Traceability

Consumers and regulators increasingly demand transparency about ingredient origins, production methods, and the product’s journey through the supply chain. Implementing effective farm-to-fork traceability systems is challenging both technically and in terms of coordinating data sharing among different partners.

8- Maintaining the Cold Chain

For a vast range of food products (dairy, meat, frozen foods, some produce), maintaining a specific temperature range during storage and transportation is non-negotiable. Establishing, operating, and monitoring an unbroken cold chain is expensive and requires specialized equipment and meticulous management.

9- Addressing Sustainability and Environmental Concerns

Growing public awareness and regulatory pressure compel companies to reduce their environmental impact. Managing water and energy consumption, minimizing waste (especially food loss and packaging waste), adopting sustainable packaging solutions, and sourcing responsibly are creating new operational and strategic challenges.

10- Integrating New Technologies Effectively

While technologies like IoT (for quality/temperature monitoring), AI (for demand forecasting), and automation offer huge potential, implementing them effectively in the food industry faces hurdles related to cost, the need for new skills, integration with existing systems, and sometimes resistance to change.

11- Overcoming Skilled Labor Shortages

Attracting and retaining workforce for various roles in the food supply chain – from farm and factory labor to quality control specialists and logistics experts – can be difficult, particularly for demanding or less desirable jobs.

How Can These Challenges Be Overcome?

Successfully navigating these obstacles requires a strategic outlook, close collaboration among all chain partners, smart investment in technology, and critically, the adoption of suitable production and supply chain strategies, which we will explore in detail in the next section.

What Are Production Strategies in the Food Industry?

Production strategies are the specific operational plans and guiding philosophies that a food business adopts to align its manufacturing and supply chain activities with its overall business goals (like growth, profitability, and customer satisfaction). They are not just sets of instructions but management approaches designed to help companies effectively leverage their resources and capabilities, navigate constraints, and overcome the unique challenges of the food industry – such as perishability, supply and demand volatility, and stringent safety requirements.

Intelligently selecting and implementing the right mix of these strategies is key to boosting efficiency, reducing costs (especially waste), enhancing product quality and safety, increasing flexibility to market changes, and ultimately building a sustainable competitive advantage in this dynamic sector. Let’s explore three fundamental and widely used strategies:

1- Lean Manufacturing

Lean manufacturing is a management philosophy focused on systematically eliminating waste (Muda) in all processes while maximizing value for the customer. Its core aim is to do things more efficiently, faster, and at a lower cost by identifying and removing any activity that doesn’t add value from the customer’s perspective.

Key Principles in the Food Industry

Identifying and Eliminating the 7 Wastes: In food, this includes overproduction (leading to expired goods), excess inventory (raw materials or finished products at risk of spoilage), waiting times between process steps (e.g., waiting for cooking or packaging), unnecessary transport, over-processing, excess motion by workers, and defects (spoiled or non-conforming products).

Value Stream Mapping (VSM): Charting and analyzing every step involved in producing a specific food item (e.g., yogurt, from milk reception to dispatch) to pinpoint bottlenecks and opportunities for waste removal.

Creating Continuous Flow: Striving for smooth, uninterrupted movement of products through the production line, rather than large batches that increase waiting times and work-in-progress inventory, helping to maintain freshness.

Implementing a Pull System: Producing only when triggered by a signal (demand) from the next stage or the customer, instead of producing based on forecasts and building stock. This significantly reduces excess inventory and the risk of obsolescence.

Fostering Continuous Improvement (Kaizen): Cultivating a culture where all employees constantly seek small and large ways to improve processes, reduce waste, and enhance quality.

Benefits in the Food Industry

Significant reduction in food waste: Due to less overproduction, lower inventory, and faster throughput.

Lower production and warehousing costs: Resulting from waste elimination and reduced need for storage space (especially costly cold storage).

Improved quality and safety: Through focus on standardized processes and error-proofing.

Increased productivity: Better utilization of time, equipment, and personnel.

Shorter lead times: Resulting from smoother flow and reduced waiting times.

Practical Example

Consider a bakery experiencing high waste levels due to frequent changes in product types (different breads, pastries). Using Lean principles, they map their value stream and identify long machine changeover times between products as a major bottleneck. By applying techniques to reduce setup times (like SMED) and standardizing some procedures, they drastically cut production line downtime. They also implement a Kanban system for key ingredients, preventing overstocking and spoilage risks. The outcome is reduced waste, increased line flexibility, and lower costs.

2- Agile Manufacturing

Agile manufacturing emphasizes flexibility, speed, and rapid responsiveness to unpredictable changes in customer needs and market conditions. The primary goal is the ability to quickly adapt to varying order volumes and mixes, and to swiftly introduce new or customized products to the market.

Key Principles in the Food Industry

High Flexibility in Production Lines: Utilizing equipment and layouts that allow for quick changes in product type, volume, or packaging with minimal cost and time.

Close Collaboration and Information Sharing: Strong, transparent communication between internal teams (Sales, Marketing, R&D, Production) and with key suppliers and customers to anticipate and react quickly to changes.

Modular or Platform-Based Production: Designing products or processes where variety or customization can be achieved by combining standard modules or components (e.g., in producing ready-to-eat salads or meal kits).

Empowered Workforce: Giving employees the authority and training to make quick decisions at the production level and solve problems locally.

Leveraging Technology for Speed: Employing tools like rapid prototyping (for new food products) and integrated information systems.

Benefits in the Food Industry

Quick response to fast-moving trends: Such as demand for organic, plant-based, gluten-free, or seasonal flavor profiles.

Reduced time-to-market for new products: Gaining a competitive edge by launching innovations faster.

Ability to manage demand volatility: Adapting to sudden increases or decreases in orders more effectively.

Increased customer satisfaction: Through the ability to offer diverse or slightly customized products.

Improved risk management: Ability to quickly shift production plans if a specific raw material supply is disrupted.

Practical Example

Imagine a natural beverage company wanting to quickly capitalize on a health drink trend. With flexible production lines capable of easily processing different fruits and vegetables and filling various bottle sizes, combined with close collaboration between R&D and marketing, the company can rapidly formulate, test-produce, and launch several new products (like celery juice or apple-ginger blends) while competitors with more rigid lines are still in the planning phase.

3- Just-in-Time (JIT) Manufacturing

Just-in-Time (often considered a component of Lean) is a strategy aimed at producing and delivering products or components exactly when they are needed – no sooner, no later. It seeks to minimize or eliminate the need for inventory buffers (whether raw materials, work-in-progress, or finished goods).

Key Principles in the Food Industry

Robust Pull System: Production at each stage is triggered only by a demand signal from the next stage.

Very Close Supplier Collaboration: Requires highly reliable suppliers capable of delivering smaller batches of materials (especially fresh, perishable ingredients) more frequently and precisely on schedule.

Reduced Setup Times: The ability to quickly switch production lines to efficiently produce smaller batches of different products.

High Quality at the Source: Since there are no buffer stocks, the quality of incoming materials and production processes must be exceptionally high to prevent line stoppages due to defects.

Optimized Plant Layout: Designing material flow paths to be short and direct, minimizing handling time.

Benefits in the Food Industry

Minimized inventory and holding costs: Drastically reduces the need for warehousing and associated costs (space, energy, management, spoilage risk).

Drastic reduction in waste due to expiration: Especially critical for ingredients and products with very short shelf lives.

Rapid visibility of problems: Any quality or delivery issue becomes immediately apparent and must be addressed quickly.

Improved cash flow: Less capital tied up in inventory.

Challenges and Considerations in the Food Industry

Heavy reliance on supplier reliability: Any supplier delay or quality issue can halt the entire production line.

Vulnerability to supply disruptions: Unexpected issues in raw material supply (e.g., crop failures, transport strikes) can quickly impact production due to the lack of buffer stock.

Need for highly accurate demand forecasting: Essential for sending the correct demand signals upstream to suppliers.

Requires efficient and reliable logistics infrastructure: To ensure frequent, on-time deliveries.

Practical Example

A large industrial bakery delivering fresh bread daily to hundreds of stores can leverage JIT principles. It establishes precise contracts with flour and yeast suppliers for daily deliveries based on that day’s exact needs. Production lines are scheduled to produce various bread types overnight and early morning, based on orders received from stores for the next day. The distribution system must also be highly efficient to get the fresh bread to stores within the first few hours of the morning. This minimizes the need for bread inventory and ensures maximum freshness but demands exceptional coordination with suppliers and logistics.

Types of Production Processes in the Food Supply Chain

Production sits at the core of the food supply chain, transforming raw materials and ideas into the products consumers need and desire. However, not all food products are made the same way. Depending on factors like product characteristics (e.g., shelf life, complexity), demand predictability, the need for customization, and shelf-life considerations, companies employ different production process models.

Choosing the right process, or often a combination of processes, directly impacts operational efficiency, inventory levels, costs, delivery lead times, customer responsiveness, and ultimately, business success. Understanding the nuances of these models is essential for anyone operating in the food industry. Let’s examine the most common types:

1- Make-to-Stock (MTS)

In this model, products are manufactured based on market demand forecasts and stored in inventory (at the factory or distribution centers) before any specific customer orders are received. The goal is to have products readily available for quick shipment upon demand.

Characteristics & Application in the Food Industry

MTS is best suited for standardized products with relatively stable, high-volume demand. Think long-shelf-life items like canned goods, pasta, UHT milk, cooking oils, bottled sauces, and many packaged snacks or confectioneries. The primary aim is to ensure consistent product availability on retail shelves.

Advantages in the Food Industry

Immediate Delivery: Products are available off-the-shelf, minimizing customer wait times.

Lower Unit Production Costs: Continuous, large-batch production typically leads to economies of scale.

Buffers Against Demand Spikes: Inventory can absorb short-term demand fluctuations or surges (e.g., during holidays).

Drawbacks & Challenges in the Food Industry

High Risk of Spoilage/Obsolescence: Inaccurate demand forecasts or sudden market shifts can lead to large amounts of unsold inventory expiring, especially for products without an extremely long shelf life.

Significant Inventory Holding Costs: Warehousing (especially temperature-controlled), handling, insurance, and the cost of capital tied up in stock can be substantial.

Less Flexibility: Slow response to changes in consumer preferences or product specifications, as existing inventory must be depleted first.

Heavy Reliance on Forecast Accuracy: The success of MTS hinges critically on the ability to accurately predict market demand.

Practical Example

A large dairy company producing UHT (long-life) milk uses an MTS model. Based on historical sales data and market analysis, they forecast monthly demand and continuously produce, sterilize, package, and store the milk. This ensures they can consistently supply supermarkets and retailers nationwide. Accurate forecasting is vital to prevent stock nearing its expiration date.

2- Make-to-Order (MTO)

In the MTO model, the production process begins only after receiving a confirmed order from a specific customer. No finished goods inventory is held beforehand.

Characteristics & Application in the Food Industry

MTO is suitable for products requiring a high degree of customization or those with very low, infrequent, or unpredictable demand. Food industry examples include custom-designed celebration cakes (wedding, birthday), bespoke catering services for specific events, production of specialized ingredients for industrial clients, or even preparing fresh meals in a restaurant kitchen upon order.

Advantages in the Food Industry

High Customization: Product is tailored exactly to the customer’s specifications.

Eliminates Obsolescence Risk: No risk of unsold finished goods expiring as production is demand-driven.

Lower Finished Goods Inventory Costs: No need to warehouse final products.

Suitable for High-Value or Specialty Items: Where holding inventory would be too costly or risky.

Drawbacks & Challenges in the Food Industry

Longer Lead Times: Customers must wait for the product to be manufactured.

Potentially Higher Unit Production Costs: Smaller batch sizes and less continuous production can increase costs.

Complex Order & Production Management: Coordinating individual orders, sourcing potentially unique ingredients (which may not be readily stocked), and scheduling production capacity can be challenging.

Sourcing Fresh Ingredients On-Demand: Procuring short-shelf-life ingredients quickly specifically for a custom order can be difficult.

Practical Example

A high-end bakery specializing in elaborate, multi-tiered wedding cakes operates on an MTO model. Clients place orders weeks or months in advance, specifying design, flavors, and size. The bakery then sources the necessary ingredients (some potentially specialized) and creates the cake just before the event according to the exact specifications. This eliminates the risk of unsold cakes but requires meticulous planning and skilled execution.

3- Mass Customization

This model attempts to combine the benefits of mass production (efficiency, lower cost) with those of customization (flexibility, meeting individual needs). It uses standardized components, ingredients, or processes for most of the operation but allows customers to personalize certain features or options at the final stages.

Characteristics & Application in the Food Industry

This approach is gaining traction. Examples include choosing toppings for a pizza, selecting ingredients for a custom salad or sandwich at a fast-casual restaurant, creating personalized gift baskets online by selecting from a predefined range of food items, or choosing specific bean types and grind levels when ordering coffee.

Advantages in the Food Industry

Provides a Sense of Personalization: Meets customer desire for choice without the full cost/time of MTO.

Maintains Relative Efficiency: Leverages standardized components and processes for bulk production.

Reduced Inventory Risk (vs. Pure MTO): Standard components can often be managed using MTS principles.

Drawbacks & Challenges in the Food Industry

Process Design Complexity: Requires designing production or assembly processes that can handle final-stage variations efficiently.

Component Inventory Management: Need to manage stock levels for all possible customization options offered.

Requires Robust Information Systems: To accurately capture, process, and communicate customized orders to the production/assembly stage.

Practical Example

An online retailer selling trail mix allows customers to create their own custom blend. The company stocks various nuts, seeds, and dried fruits in bulk (MTS). When a customer places an order online specifying, for instance, 200g almonds, 100g walnuts, and 50g dried cranberries, the fulfillment team portions these items from the bulk containers, mixes them, and packages them for the specific customer order.

4- Engineer-to-Order (ETO)

In the ETO model, not only production but also the product design itself is initiated only after receiving a customer order based on unique requirements. Each order is essentially a distinct project.

Characteristics & Application in the Food Industry

ETO is less common for final consumer food products but relevant in supporting sectors of the industry. Examples include designing and building customized food processing machinery or entire production lines for a specific factory’s needs, or developing a completely new, proprietary flavor, ingredient formulation, or functional blend for a large food manufacturer by a specialized ingredient company. Producing highly specific sauces or seasonings exclusively for a major restaurant chain could also fall into this category.

Advantages in the Food Industry

Delivers Highly Customized, Unique Solutions.

Potential for High Profit Margins: Due to the specialized, bespoke nature of the work.

Builds Strong, Strategic Relationships with key clients.

Drawbacks & Challenges in the Food Industry

Very Long Lead Times: Requires a design and engineering phase before production can begin.

Very High Costs: Both for the extensive design phase and non-mass production.

Requires Deep Technical Expertise and Specialization.

Complex Project Management: Each order must be managed individually.

Practical Example

A meat processing company wants to launch a unique plant-based sausage with a specific texture and flavor profile. They approach a food processing equipment manufacturer with their detailed requirements. The equipment company designs, builds, and installs custom mixing, filling, and cooking machinery tailored specifically for this new product line based on the client’s unique needs.

5- Assembly-to-Order (ATO)

ATO is an intermediate model between MTS and MTO. Standardized components or sub-assemblies are produced and stocked in advance (MTS), but the final assembly of the finished product happens only after a customer order is received, often allowing for some customization from pre-defined options.

Characteristics & Application in the Food Industry

This is similar to Mass Customization and sometimes used interchangeably. It applies where the final product can be quickly assembled from pre-made components. Examples include assembling customized gift baskets from a selection of stocked food items (chocolates, wines, cheeses), or the final assembly and packaging of meal kits where core ingredients are pre-portioned and only combined based on the specific kit ordered.

Advantages in the Food Industry

Faster Delivery than MTO: As components are pre-produced.

More Variety/Customization than MTS: Customers have choices at the assembly stage.

More Efficient Inventory Management than MTO: Standard components can be forecast and stocked.

Drawbacks & Challenges in the Food Industry

Limited Customization: Restricted to the pre-defined assembly options.

Requires Accurate Inventory Management of all Components.

Needs an Efficient and Fast Final Assembly Process.

Practical Example

An online business offers customized breakfast boxes. They stock various standard items like packaged bread types, small cheese portions, individual jams, juices, etc. (MTS). Customers select their preferred combination online (e.g., specific bread, jam flavor, juice type). The fulfillment team then assembles these selected items into a box based on the customer’s order just before shipping.

Choosing the Right Mix

In reality, many food companies utilize a hybrid approach, employing different models for different product lines or stages of their business. Selecting the most suitable strategy (or combination) depends heavily on factors like product characteristics (shelf life, complexity), demand patterns (stable vs. volatile), customer expectations for customization, and the company’s own operational capabilities. Making an informed choice based on careful analysis is crucial for supply chain success in the food industry.

Two Pillars of Supply Chain Integration in the Food Industry: Collaboration and Coordination

An efficient food supply chain isn’t just a sequence of individual companies; it’s an integrated ecosystem where all players work towards common goals. Integration involves weaving together processes, information, and objectives among different stakeholders to enhance overall performance, reduce costs (especially waste), and ensure end-consumer satisfaction. In an industry dealing with products sensitive to time, quality, and safety, this integration is more critical than ever.

This integration primarily rests on two main pillars: Collaboration and Coordination. While related, they represent distinct but complementary aspects of working together:

1- Collaboration in the Food Supply Chain

Collaboration means actively working together towards shared objectives. It goes beyond simple transactional relationships to involve the voluntary sharing of information, joint planning, collective decision-making, and often, the sharing of risks and rewards among supply chain partners (like farmers, ingredient suppliers, manufacturers, packaging companies, distributors, and retailers).

Key Dimensions of Collaboration in the Food Industry

Sharing Critical Information: This includes point-of-sale (POS) data, retail inventory levels, demand forecasts, promotional plans, raw material quality specifications, and traceability data.

Joint Planning: Working together on production schedules, demand forecasting (e.g., through CPFR processes), inventory management (like Vendor-Managed Inventory – VMI), and new product introductions.

Collaborative Product Development: Partnerships between manufacturers and ingredient suppliers or packaging companies to innovate and create better, safer, or more sustainable products.

Shared Risk Management: Working together to identify, assess, and mitigate supply chain risks, such as food safety hazards, raw material price volatility, or weather-related disruptions to agriculture.

Benefits of Collaboration in the Food Industry

Increased Transparency and Visibility: All partners gain a clearer view of events and requirements across the entire chain.

Faster, More Effective Response to Market Changes: Enables quicker adaptation to demand fluctuations or supply issues.

Enhanced Innovation: Exchanging knowledge and ideas among partners often leads to process and product improvements.

Reduced Risks: Better ability to proactively identify and address potential problems (like contaminated ingredients).

Stronger, Long-Term Relationships: Built on trust and mutual benefit.

Practical Example of Collaboration

Consider a large supermarket chain and a supplier of fresh dairy products (like milk and yogurt). They decide to collaborate to tackle the common problem of stockouts or overstocking on shelves. The retailer shares daily sales data and current store inventory levels automatically with the producer. Together, they develop demand forecasts and jointly plan promotional activities. The producer then adjusts its production and delivery schedules based on this shared information. This collaboration leads to reduced waste (fewer expired returns), increased sales (due to better availability), and higher customer satisfaction.

Rethinking Transportation in the Supply Chain

Models & Methods2- Coordination in the Food Supply Chain

Coordination focuses more on the synchronization of activities, processes, and the physical flow of goods throughout the supply chain. The main goal is to ensure that the right activities happen at the right time, in the right sequence, and with minimal waste of resources, enabling a smooth and efficient flow of materials and products.

Key Dimensions of Coordination in the Food Industry

Precise Timing of Activities: Coordinating harvest times with transportation schedules, factory reception times, production line schedules, and dispatch to distribution centers or stores to maximize freshness.

Synchronized Flow of Materials and Information: Ensuring that order details, transport information, and quality data move seamlessly alongside the physical goods.

Integrated Logistics Management: Coordinating warehousing, transportation (especially the cold chain), and distribution to prevent delays, bottlenecks, and reduce costs.

Accurate Execution of Inventory Principles: Coordinating the implementation of methods like FEFO (First-Expired, First-Out) across all storage and distribution points.

Aligning Production with Actual Demand: Using demand signals to fine-tune production schedules and prevent inventory pile-ups.

Benefits of Coordination in the Food Industry

Significant Reduction in Food Waste and Spoilage: Achieved by minimizing waiting times and dwell times throughout the chain.

Improved Service Levels and On-Time Delivery: Ensures fresh, safe products reach the customer when expected.

Optimized Inventory Management: Prevents both stockouts and costly overstock situations.

Lower Operational Costs: Through better utilization of transport capacity, warehouses, and production lines.

Enhanced Overall Supply Chain Efficiency.

Practical Example of Coordination

Think of a company processing frozen vegetables. Its success heavily depends on precise coordination between contracted farms, harvesting teams, refrigerated transport fleet, and the rapid freezing (IQF) lines at the factory. The harvest schedule for vegetables (like peas) must be perfectly synchronized with the factory’s processing capacity to ensure the produce is frozen at its peak freshness and quality. Any delay in transport or waiting time before freezing can severely impact the final product quality. Tight coordination of these steps ensures a high-quality output and minimizes waste.

Key Stakeholders in Food Supply Chain Integration

Successful collaboration and coordination require the active participation and alignment of all links in the supply chain. Each stakeholder plays a unique role in the flow of food products, and effective integration is only possible by understanding their interconnected roles and needs. The most important stakeholders include:

1- Raw Material Suppliers

This group includes farmers, ranchers, fishermen, growers, and producers of processed raw materials (like flour, sugar, crude oils, or additives). They are the starting point of the chain, and the quality, quantity, and timing of their deliveries directly impact the entire process. Close collaboration (e.g., on demand forecasts) and coordination (e.g., on harvest and delivery schedules) with this group are vital for ensuring quality and preventing shortages or surpluses.

Practical Example: A potato chip manufacturer needs potatoes with specific characteristics (size, starch content, sugar levels). Collaborating with farmers on planting suitable varieties, adhering to good agricultural practices, and joint planning for harvest and delivery helps the factory receive consistent, high-quality raw materials, while the farmer gains supply certainty.

2- Food Manufacturers & Processors

These are the operational core of the chain, transforming raw materials into finished goods ready for the market through various processes (cooking, mixing, packaging, etc.). They must coordinate closely with raw material suppliers upstream and meet the needs and orders of distributors and retailers downstream. Ensuring quality, safety, production efficiency, and inventory management are their primary responsibilities.

Practical Example: A company producing canned goods must align its production schedule with sales forecasts and wholesaler orders. Simultaneously, it needs to ensure timely receipt of raw materials (like beans, vegetables, meat, and cans) from various suppliers and execute cooking, sterilization, and packaging processes according to strict safety and quality standards.

3- Distributors & Wholesalers

These intermediaries play a key role in getting finished products from manufacturers to a large number of retailers or business customers (like restaurants and hotels). They typically operate extensive warehousing and transportation networks, managing regional inventory, taking orders from retailers, and ensuring timely delivery. Their coordination with both manufacturers (for supply) and retailers (for delivery) is essential.

Practical Example: A national distribution company receives diverse food products (like oil, rice, tea) from various manufacturers, stores them in regional warehouses, and handles last-mile distribution to thousands of supermarkets and smaller shops across the country based on their orders.

4- Retailers

This group represents the final point of contact with the end consumer and includes supermarkets, hypermarkets, chain stores, convenience stores, specialty shops, and online grocers. Their role involves making products accessible, managing shelf space, executing promotions, and providing information to shoppers. Collaboration with distributors and manufacturers on forecasting, in-store inventory management, and promotional campaigns is crucial to avoid stockouts or overstocking.

Practical Example: A large hypermarket, beyond placing regular orders, can share point-of-sale (POS) data for key products with its main suppliers, allowing them to better adjust production and shipments. Coordinated planning with distributors is also vital before running major discount campaigns to ensure sufficient stock availability.

5- Logistics Service Providers (3PLs)

These companies offer specialized services in transportation, warehousing (especially temperature-controlled), customs brokerage, and other logistics functions to manufacturers, distributors, or retailers. Given the complexities of food logistics (particularly cold chain requirements and the need for speed), 3PLs play a significant role in supply chain efficiency and integration. Close coordination with them is vital.

Practical Example: An ice cream manufacturer outsources the transportation of its products from the factory to regional depots and then to retail stores to a logistics company specializing in refrigerated and frozen transport. This 3PL is responsible for maintaining the correct temperature throughout the journey, optimizing routes, and ensuring on-time delivery, requiring tight coordination with both the factory and the stores.

To learn more about the crucial role of 3PLs in the food supply chain, explore our detailed article on the topic.

6- Packaging Suppliers

Packaging is critical in the food industry for preserving quality, ensuring safety, extending shelf life, providing convenience, and conveying brand messages. Suppliers of packaging materials and containers (cartons, glass jars, plastic films, metal cans, etc.) must deliver suitable, consistent quality packaging that meets legal and hygiene requirements on time to manufacturers. Collaboration on designing innovative and sustainable packaging solutions is also increasingly important.

Practical Example: A baby food company packaging its products in small glass jars requires close collaboration with its glass supplier to ensure the quality, hygiene standards, and timely delivery of jars and lids. Any defect in the packaging could compromise product safety.

7- Technology Providers

This group includes companies providing the software (like ERP, SCM, WMS systems, e-commerce platforms, data analytics tools such as those offered by Foodex Digital) and hardware (like IoT sensors for temperature monitoring, automation equipment, tracking systems) needed to manage and optimize the supply chain. They are key enablers of digitalization and increased intelligence in food supply chains.

Practical Example: A large food distributor uses specialized route optimization and fleet management software provided by a tech company to streamline its delivery operations. This software helps reduce transportation costs and improve delivery timeliness.

8- Regulatory Bodies

Government agencies and regulatory authorities (like the FDA in the US, EFSA in Europe, or national bodies like Ministries of Health or Agriculture) play a crucial and influential role by setting and enforcing laws and standards related to food safety, quality, labeling, import/export, and hygiene. All stakeholders must be aware of and comply with these regulations.

Practical Example: A national food safety agency sets strict limits for pesticide residues in fresh produce and defines mandatory information for nutrition labels. All producers and importers must adhere to these rules, and agency inspectors monitor compliance.

9- End Consumers

Although at the end of the chain, the entire supply chain ultimately exists to meet their needs, wants, and expectations. Consumer preferences regarding price, quality, taste, health, convenience, sustainability, and ethical considerations are the primary drivers of change and innovation throughout the food supply chain. Gathering their feedback and understanding consumption trends is vital for long-term success.

Practical Example: Growing consumer awareness and concern about sugar intake has prompted many beverage and confectionery manufacturers to develop lower-sugar or naturally sweetened product lines, impacting their ingredient sourcing and formulation strategies.

The Importance of Stakeholder Alignment

As seen, the food supply chain is a complex network of diverse players with different roles and interests. Successfully integrating this chain depends on recognizing the importance of each stakeholder and striving to create alignment, collaboration, and coordination among them:

Collaboration among these stakeholders enhances transparency, reduces risk, and drives innovation.

Coordination of their activities helps minimize waste, optimize logistics, and improve on-time delivery.

Ultimately, the success of the entire chain relies on the success of its key individual stakeholders and their ability to work together effectively.

What Is Quality Management in the Food Production and Supply Chain?

Quality management in the food industry extends far beyond simply producing a “good” product. It’s a comprehensive, systematic set of activities aimed at ensuring the safety, wholesomeness, compliance with standards, and fulfillment of customer quality expectations at every step of the supply chain, from farm to table. It encompasses processes, raw materials, equipment, personnel, and the working environment, playing a vital role in building consumer trust, protecting brand reputation, and meeting legal requirements. Modern quality management emphasizes preventing problems rather than just detecting defects.

The core components of quality management in the food industry include:

1- Quality Planning

This initial phase involves setting clear quality and safety objectives for products and processes. It includes defining precise product specifications (sensory, physical, chemical, microbiological attributes), identifying applicable standards (national regulations, international standards like ISO 22000, specific customer requirements), determining Critical Control Points (CCPs) based on HACCP principles, establishing production methods, and setting acceptance criteria for raw materials and finished goods. All of this must be clearly documented.

2- Quality Assurance (QA)

QA comprises the planned and systematic actions necessary to provide adequate confidence that a product or service will satisfy given requirements for quality and safety. QA is process-oriented and focuses on preventing defects. Implementing and maintaining management systems like GMP (Good Manufacturing Practices), GHP (Good Hygiene Practices), and especially HACCP (Hazard Analysis and Critical Control Points) – designed to identify, evaluate, and control food safety hazards – forms the backbone of QA in the food sector. Internal and external audits are also part of QA.

3- Quality Control (QC)

QC involves the operational techniques and activities (inspection, measurement, testing) used to verify that actual product or process characteristics conform to the predefined requirements established during quality planning. QC is product-oriented and focuses on detecting defects or non-conformances. Sampling incoming raw materials, in-process materials, and finished products to perform various tests (sensory, chemical, microbiological, physical checks like weight or seal integrity) are core QC activities.

4- Continuous Quality Improvement (CQI)

Quality management is a dynamic process. Using data gathered from QC tests, customer feedback, audit results, and process performance evaluations, opportunities for improvement are constantly sought to enhance quality, safety, and efficiency. This improvement cycle (like the Plan-Do-Check-Act cycle) helps the organization continually optimize its performance.

Key Quality Control Techniques in the Food Industry

Various techniques are employed to effectively implement QC and support QA efforts:

1- Statistical Process Control (SPC)

This technique uses statistical tools (especially control charts) to monitor and control production processes over time. The goal is to detect any drifts from the desired state or out-of-control conditions early, allowing for corrective action before defective products are made. Food industry example: Continuously monitoring milk pasteurization temperatures, fill weights of packaged pasta, or the pH of jam during production using control charts.

2- Inspection and Testing

This encompasses a wide range of activities to directly assess the quality of materials and products:

Visual Inspection: Checking color, appearance, presence of foreign materials, product uniformity, packaging integrity.

Sensory Evaluation: Assessing taste, smell, texture, and appearance using trained panels.

Physical Testing: Measuring weight, volume, dimensions, viscosity, freezing/melting points, seal integrity checks.

Chemical Testing: Measuring pH, moisture, fat, protein, salt, sugar, vitamins; detecting additives, pesticide residues, or antibiotics.

Microbiological Testing: Total plate counts, identification of pathogens (e.g., Salmonella, Listeria), yeast and mold counts.

3- Failure Mode and Effects Analysis (FMEA)

FMEA is a systematic, proactive method to identify potential failure modes in a process (e.g., sausage production) or product, analyze their causes and effects, and prioritize them based on severity, likelihood of occurrence, and detectability. Control measures are then designed to mitigate high-risk items. This technique is closely related to the hazard analysis step in HACCP and helps to better identify and control food safety hazards (biological, chemical, physical).

4- Root Cause Analysis (RCA)

When a problem occurs (e.g., customer complaints about an off-flavor, a sudden increase in product returns), RCA employs various methods (like the 5 Whys or Ishikawa diagrams) to dig deep and identify the underlying, fundamental cause(s) of the issue, rather than just addressing superficial symptoms. The goal is to find the root cause and implement corrective actions to prevent recurrence.

5- Six Sigma

Six Sigma is a data-driven, project-focused management approach aimed at improving quality by drastically reducing defects and process variability. It strives for near perfection (less than 3.4 defects per million opportunities) using a structured five-phase methodology called DMAIC:

Define: Clearly define the problem, project goals, and customer requirements.

Measure: Collect data and measure the current performance of the process.

Analyze: Analyze the data to identify the root causes of defects and problems.

Improve: Design, test, and implement solutions to eliminate root causes.

Control: Monitor and control the improved process to ensure results are sustained. Food industry example: A project to reduce

weight variations in packaged snacks or decrease cleaning time on a production line using the DMAIC methodology.

Practical Example: Applying Quality Techniques in a Food Factory

Consider a factory producing mayonnaise. To ensure product quality and safety, they might use a combination of these techniques:

Planning: They define strict standards for viscosity, taste, color, pH, and emulsion stability, plus microbiological standards for raw materials (eggs, oil, vinegar) and the final product. They identify CCPs (like egg pasteurization) based on HACCP.

QA: They implement a HACCP system and conduct regular audits. They enforce Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP) and train employees accordingly.

QC: Upon receipt, they sample and test incoming oil, vinegar, and pasteurized eggs for quality and microbiological safety (Inspection & Testing). During production, they use SPC control charts to monitor the pH and viscosity of the mayonnaise. They also test the final product for sensory, chemical, and microbiological parameters.

Improvement: If customer complaints about oil separation increase, they use RCA (perhaps an Ishikawa diagram) to find root causes (e.g., issues with homogenization, incorrect temperature, oil quality). They might then use techniques like Design of Experiments (DOE – part of the Six Sigma toolkit) to improve the formulation or process (Improvement). They could also use FMEA proactively to anticipate and prevent other potential stability issues.

Key Quality Control Tools

A set of basic graphical and statistical tools, often called the “7 Basic Tools of Quality,” are widely used for data analysis, problem-solving, and decision-making in quality management:

1- Check Sheet

A simple, structured form for easily collecting and tallying data on the frequency of specific events or defects over a certain period. (Example: Recording the number of underweight sauce pouches per shift).

2- Histogram

A bar chart showing the frequency distribution of numerical data. It helps visualize the shape of the data distribution, the central tendency, and the amount of variation in a process or quality characteristic. (Example: Histogram of sauce pouch weights to see if the distribution is normal and centered near the target weight).

3- Pareto Chart

A bar chart that ranks causes or defect types by frequency of occurrence (from highest to lowest), usually including a cumulative frequency line. Based on the Pareto principle (80/20 rule), it helps identify the “vital few” problems causing the majority of issues, allowing for prioritized improvement efforts. (Example: Pareto chart of sauce customer complaint types, showing that 80% of complaints relate to just 2 or 3 main issues).

4- Cause-and-Effect Diagram (Ishikawa or Fishbone Diagram)

A brainstorming tool used to identify all potential causes contributing to a specific problem or effect. Causes are typically organized into major categories like People, Machines, Materials, Methods, Measurement, and Environment. (Example: Using a fishbone diagram to brainstorm all possible causes for oil separation in mayonnaise).

5- Scatter Diagram

A graph used to explore the relationship between two numerical variables. By plotting data points on a two-dimensional chart, it helps visualize whether a correlation (positive, negative, or none) exists between the variables. (Example: Plotting sauce storage temperature against the degree of oil separation to see if there’s a relationship).

6- Control Chart

A line graph that plots a quality characteristic or process measurement over time against upper and lower control limits (UCL/LCL). It’s the primary tool of SPC, helping to distinguish between normal process variation (common causes) and unusual variation due to specific problems (special causes) that require investigation. (Example: Control chart monitoring the pH of the sauce during production).

7- Flowchart

A graphical representation of the steps in a process using standard symbols. Flowcharts help in understanding the process flow, identifying complex or redundant steps, and pinpointing areas needing improvement or control. (Example: Drawing a flowchart of the entire mayonnaise production process from raw material receiving to final packaging).

The Future of Food Production and Supply Chains: Trends and Challenges

The food production and supply chain landscape is evolving at an unprecedented pace. Emerging technologies, shifting consumer expectations, and global dynamics are constantly reshaping the industry. Businesses that understand these trends, adapt proactively, and prepare for the challenges ahead will be best positioned to lead in the future. Let’s explore the most significant trends and challenges shaping the future of food supply chains.

Key Trends Shaping the Future Food Industry

1- Digitalization and Smart Food Factories

This involves the widespread adoption of technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), Big Data analytics, and cloud computing to bring intelligence to every facet of the food supply chain.

Application in the Food Industry: IoT sensors monitoring real-time temperature, humidity, and other conditions in warehouses, shipping containers, and even smart packaging; AI optimizing demand forecasting for perishable goods, production scheduling, and detecting patterns indicating spoilage or fraud; machine vision systems for automated quality control (checking color, size, shape, defects); integrated platforms enabling end-to-end traceability from farm to fork.

Practical Example: A large dairy processor uses IoT sensors on milk transport tankers to continuously monitor temperature from farm collection to factory arrival, receiving instant alerts for any deviations. AI algorithms analyze sales data and other factors to recommend optimal production schedules for various yogurts and cheeses.

Opportunities: Significant gains in efficiency, waste reduction, enhanced quality and safety, greater transparency, and data-driven decision-making.

2- Advanced Automation and Robotics

The increasing use of robots (especially collaborative robots or ‘cobots’ working alongside humans) and advanced automation systems to perform repetitive, strenuous, hazardous, or high-precision tasks in food production lines and warehouses.

Application in the Food Industry: Robotics in harvesting (developing field), material handling and palletizing, primary and secondary packaging (e.g., placing items into cartons), precision processes like cutting or decorating, and automated cleaning/sanitation of production lines.

Practical Example: In a biscuit factory, high-speed robots handle the delicate task of picking and placing biscuits into primary packaging and then loading these packs into larger cases, operating with high precision and speed without manual handling, thus improving both productivity and hygiene.

Opportunities: Reduced labor costs, increased production speed and capacity, improved worker safety, reduced errors, and greater product consistency.

3- Sustainability and the Circular Economy

Growing pressure from consumers, investors, and regulators is pushing the food industry to minimize its environmental footprint and adopt more sustainable models.

Application in the Food Industry: Reducing water and energy consumption in processing; utilizing renewable energy sources; minimizing food loss and waste across the entire chain; designing recyclable, biodegradable, or reusable packaging (replacing plastics); utilizing processing by-products for other value-added streams (circular economy principles); and sourcing ingredients responsibly and sustainably (sustainable agriculture/fisheries).

Practical Example: A juice company dries the fruit pulp left over from juice extraction and sells it as animal feed or for fiber production instead of discarding it. It also uses recycled plastic for its bottles and implements water-saving programs in its plant.

Opportunities: Cost savings (less waste, lower energy bills), enhanced brand image attracting conscious consumers, meeting regulatory requirements, increased resilience against resource scarcity.

Key Differences Between Traditional Trade and Supermarkets

Modern Supply Chain4- Personalization and Flexible Production

Rising consumer demand for food products tailored to individual needs and preferences (specific dietary requirements, allergies, taste profiles) necessitates production systems capable of managing this variety cost-effectively.

Application in the Food Industry: Expansion of Mass Customization and Assembly-to-Order models enabled by digital technology; modular and flexible production lines; emerging uses of food 3D printing for creating specific shapes or textures on a smaller scale.

Practical Example: A meal kit startup allows customers to select weekly recipes and ingredients based on their dietary needs (e.g., low-calorie, vegan, gluten-free) and family size. Pre-portioned ingredients are then assembled and shipped in appropriate packaging.

Opportunities: Increased customer loyalty, catering to niche markets, creating competitive differentiation.

5- Enhanced Transparency and Advanced Traceability

There’s a growing demand for clear information about ingredient origins, production methods, product composition, and journey through the supply chain, driven by informed consumers, regulatory bodies, and the need for rapid crisis management (like recalls).

Application in the Food Industry: Utilizing technologies like blockchain to create secure, immutable ledgers recording transactions and events along the chain; using advanced QR codes or NFC tags on packaging to provide consumers with detailed product information; implementing integrated internal and cross-company traceability systems.

Practical Example: A premium coffee producer uses a blockchain-based system allowing consumers to scan a code on the package and see detailed information about the farm where the beans were grown, harvest dates, processing methods, quality certifications, and the shipping path.

Opportunities: Increased consumer trust, combating food fraud, more efficient recall management, validating quality or sustainability claims.

Emerging Challenges Facing the Food Industry

Alongside these opportunities, significant challenges loom that the food industry must navigate:

1- Increasing Supply Chain Disruptions

Global events like extreme weather linked to climate change, pandemics affecting labor and logistics, infrastructure failures, and geopolitical instability are likely to cause more frequent and severe disruptions to raw material access, logistics, and costs, making supply chain resilience paramount.

2- Intensifying Pressure on Natural Resources

A growing global population and shifting consumption patterns are straining vital resources like fresh water, arable land, and marine ecosystems. Resource scarcity and competition can drive up raw material costs and threaten long-term production sustainability.

3- Rising Energy and Logistics Costs

Volatile energy prices and the push for decarbonization can significantly increase operational costs, particularly for energy-intensive processes (like cooking, freezing) and transportation logistics (especially the cold chain).

4- Workforce Shifts and Skills Gaps

Automation and digitalization are changing the nature of jobs in the food industry. While demand for traditional labor may decrease in some areas, the need for IT specialists, data analysts, robotics engineers, and skilled technicians to operate advanced equipment is growing, creating challenges in recruitment, training, and retention.

5- Growing Regulatory Complexity

Regulations concerning food safety, labeling (e.g., transparency on allergens or GMOs), sustainability (e.g., plastic packaging, carbon emissions), and international trade are continuously becoming stricter and more complex globally.

6- Cybersecurity and Data Privacy Threats

As digitalization increases, food supply chains become more vulnerable to cyberattacks (which could disrupt production or distribution) and data breaches (especially concerning traceability records or consumer information).

7- Combating Food Fraud

Economically motivated adulteration (like substituting cheaper ingredients, mislabeling origin or quality, selling expired products) remains a major challenge, threatening consumer trust and public health, requiring advanced detection methods, robust traceability, and stricter oversight.

How Food Businesses Can Prepare for the Future

Invest in Digital Transformation: Embrace key technologies like IoT, AI, and data analytics to optimize operations and enable smarter decisions.

Strengthen Collaboration and Transparency: Build stronger, more open relationships with all supply chain partners.

Enhance Flexibility and Resilience: Design supply chains that can withstand disruptions and recover quickly (e.g., through supplier diversification).

Prioritize Sustainability: Integrate sustainable practices into all aspects of the business, from sourcing to packaging.

Invest in the Workforce: Train and upskill employees to work with new technologies and foster a culture of continuous improvement.

Preparing as a Supply Chain Professional in the Food Industry

To succeed in the future food supply chain environment, professionals should:

Be Lifelong Learners: Stay updated on emerging technologies, market trends, and industry best practices.

Develop Analytical and Digital Skills: Proficiency in data analysis, understanding algorithms, and using digital tools will be essential.

Cultivate a Systems Thinking Mindset: Understand the complex interconnections within the supply chain and the impact of decisions on the entire system.

Build Strong Communication and Collaboration Skills: Work effectively with diverse internal teams and external partners.

Learn more How to Become a Supply Chain Analyst in the Food and Beverage Industry

Food Production and Supply Chain Management: Final Summary

As we’ve explored throughout this comprehensive guide, managing production and the supply chain in today’s dynamic world, especially within the critical and sensitive food industry, involves far more than just manufacturing and moving goods. It’s a complex blend of science, art, and technology requiring an integrated, strategic, and forward-looking approach to optimize the flow of materials, information, and value from the farm to the final consumer’s table. Success in this competitive arena hinges on mastering the industry’s unique challenges, from managing perishability and ensuring safety to responding to market volatility and embracing sustainability.

A Recap of Key Learnings from This Article

The food production process encompasses multiple stages, from design and sourcing through manufacturing, rigorous quality control, appropriate packaging, and efficient distribution, each demanding careful attention.

Specific food industry challenges like perishability, cold chain requirements, agricultural supply variability, stringent safety and quality mandates, and sustainability pressures require tailored solutions.

Production strategies such as Lean (waste reduction), Agile (flexibility), and Just-in-Time (inventory minimization) are powerful tools for overcoming challenges and achieving operational goals, provided they are chosen and implemented appropriately for the business context.

Different production process models (MTS, MTO, ATO, etc.) offer distinct advantages and disadvantages; selecting the optimal mix for various product portfolios impacts overall chain efficiency.

Supply chain integration, built on the pillars of collaboration (shared information and goals) and coordination (synchronized activities) among all key stakeholders (from suppliers to consumers, including service and technology providers), is essential for success.

Comprehensive quality management, focusing on prevention (QA and HACCP) and diligent control (QC and testing) using appropriate tools and techniques, is fundamental to food safety and consumer trust.

The future of the industry is intertwined with trends like digitalization, automation, sustainability, personalization, and the need for greater transparency, requiring businesses to prepare for these shifts and associated challenges.

The Path Forward: Recommendations for Food Industry Players

Building a strong, efficient, and future-ready food supply chain requires focusing on several key imperatives:

Strengthen Collaboration and Transparency: Cultivating trust-based relationships and promoting data sharing with key partners upstream and downstream not only boosts efficiency but also enhances resilience against disruptions.

Embrace Digital Technology Wisely: Purposefully leveraging tools like IoT for monitoring, AI for prediction and analysis, and integrated platforms can enhance visibility, traceability, and decision-making across the chain. Using integrated, data-driven platforms can play a key role in facilitating this collaboration, increasing transparency, and optimizing decisions.

Commit Seriously to Sustainability: Integrating environmental and social considerations into all strategies, from responsible sourcing to waste reduction and sustainable packaging, is no longer optional but a necessity for brand reputation and future viability.

Foster a Culture of Continuous Improvement and Innovation: Encouraging employees to find better ways of working, embracing change, and investing continually in learning and upgrading skills and knowledge.

To deepen your knowledge and find more practical solutions, we invite you to explore other expert articles in our Supply Chain Optimization category on the Foodex Magazine.